OTF1200X-5-III-F3LV is a CE certified split 5" (O.D) three-zone tube furnace, which can achieve faster heating up to 1200oC and create a different thermal gradient by adjust three zone temperature. The furnace includes all accessories for immediate use. It is an excellent furnace for annealing, diffusing and sintering sample in various atmospheres.

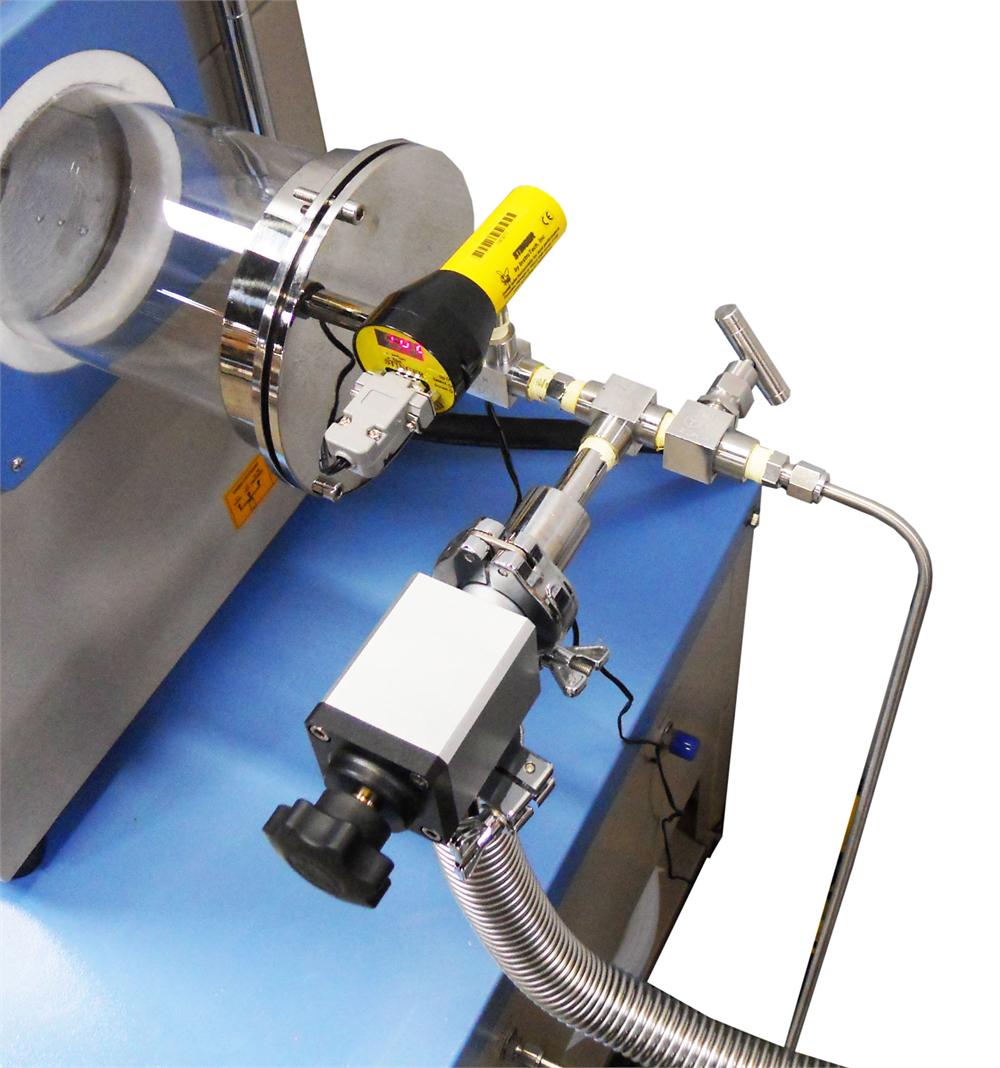

- One 5" O.D x 1400mm L fused quartz tube and one pair of vacuum sealing flanges with pressure gauge.

- Three 30 segments temperature controllers are installed with K type thermal couple. Microprocessor-based self-tuning PID control provides excellent control without overshootingand +/- 1 oC accuracy.

- 800mm long sliding rail is installed with one end flange to make loading & unload sample at easy.

- Two mobile carts are included to support furnace and sliding rail.

- Three flowmeters (range: 0-100 ml/min, 0-160 ml/min, 0-250 ml/min) are installed in one of mobile cart, which allow to use three types of gas during heat treatment.

- One mechanical pump with KF25 adaptor and SS pipe are included with furnace.

- One digital vacuum gauge is installed on the flange for easy vacuum pressure reading upto10 -4 torr.

- Click picture below to enlarge and to see details.

|

|

|

|

|

digital vacuum gauge,

SS vacuum pipe & ball

valve with KF25 adaptor

garantee 10-2 torr vacuum

|

2" Quartz boat sitting on the

slide rail holder is ready used

for diffusion, oxidation and anneal.

|

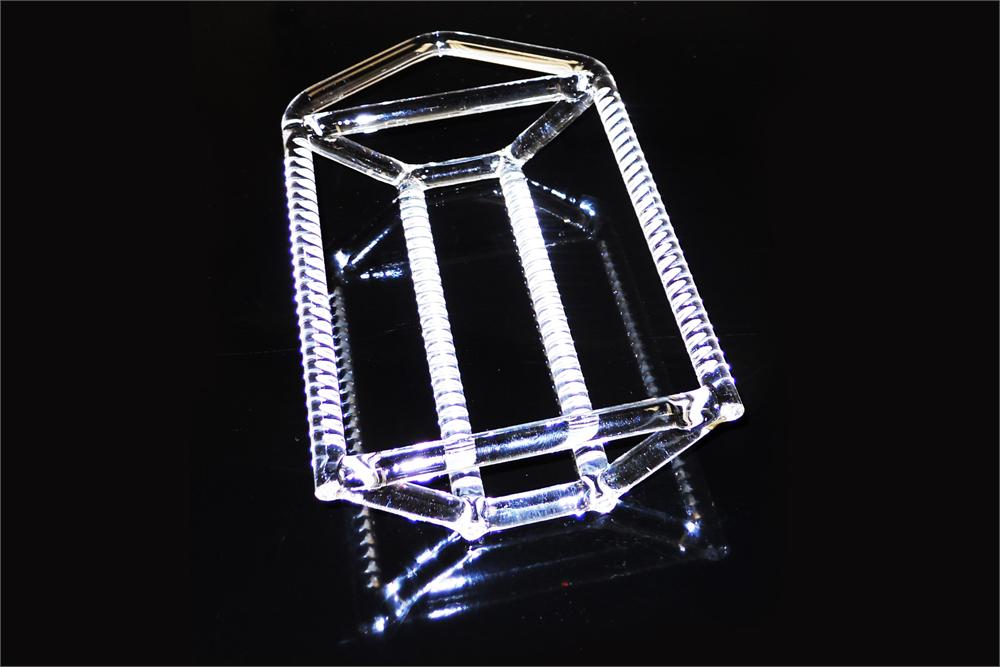

5" Quartz tube can

accommodate 4" quartz

wafer boat without holder.

|

|

Furnace structure |

|

|

Voltage |

|

|

Max. Temperature |

1200 oC |

|

Continuous Temperature |

1100 oC |

|

Max. Heating Rate |

<= 20 oC /min |

|

Tube Size and Flange |

|

|

Heating Zone Length |

Three zones: (900mm, 36" in total)

· Zone 1: 229mm (9")

· Zone 2: 457mm (18.0")

· Zone 3: 229 mm (9") |

|

Constant Temp. Zone |

|

|

Temperature Controllers |

|

|

Temperature Accuracy |

+/- 1oC |

|

Heating Element |

Fe-Cr-Al Alloy doped by Mo |

|

Dimension |

1080 X 430 x 600mm |

|

Net Weight |

about 70 kg |

|

Warranty & Certificate |

|

|

Shipping package size after crating |

|

|

Shipping weight |

|

|

Mobile Cart & Flow meters |

Two mobile carts are included. Gas mixing controls (range: 0-100 ml/min, 0-160 ml/min, 0-250 ml/min) are installed on one cart that allows three types of gases to operate during heating treatment. |

| 功能特点 |

|---|

- 双层壳体,配有冷系统,炉体采用高纯度氧化铝多晶纤维保温材料。

- 内炉膛表面涂有美国进口氧化铝涂层,可以提高反射率和保护炉膛洁净度。

- 一端法兰配有滑轨,便于样品装卸;另一端法兰装有数字真空计。

- 采用三个独立PID控制器 ,可以设置30段升降温程序,设有过热和断偶保护功能。

- 已通过CE认证。

| 技术参数 | |

|---|---|

| 安装条件 | 本设备要求在海拔1000m以下,温度25℃±15℃,湿度55%Rh±10%Rh下使用。 |

| 水 | 不需要 |

| 电 | AC220V 50Hz,必须有良好接地 |

| 气 | 设备腔室内需充注气体,需自备气瓶气源 |

| 工作台 | 尺寸1600mm×600mm×700mm,承重150kg以上 |

| 通风装置 | 需要 |

| 电源 | 单相AC 208-240V 50/60Hz 7KW (40A保险丝) |

| 石英管 | 外径Ø125mm,内径120mm,长1400mm,带有一对真空密封法兰 |

| 加热元件 | 掺钼铁铬铝合金电阻丝 |

| 加热区域 | 温区I长229mm,温区II长457mm,温区III长229mm,总长915mm |

| 恒温区域 | 三个温区为同一温度时为625mm,温区II为110mm |

| 工作温度 | *高1200℃,连续工作1100℃ |

| *大升降温速率 | 20℃/min |

| 控温精度 | ±1℃ |

| 热电偶 | K型 |

| 浮子流量计 | 3个,量程0-100ml/min、0-160ml/min、0-250ml/min |

| 数字真空计 | 10-4torr |

| 管式炉尺寸 | 1080mm×430mm×600mm |

| 重量 | 70kg |

免责声明:本站产品介绍内容(包括产品图片、产品描述、技术参数等),仅供参考。可能由于更新不及时,或许导致所述内容与实际情况存在一定的差异,请与本公司客服人员联系确认。本站提供的信息不构成任何要约或承诺,科晶公司不定期完善和修改网站任何信息,恕不另行通知。